How To Integrate IoT with AI for Smart Manufacturing Solutions?

AI for smart manufacturing has become a part of everyday factory life. It’s not just an idea for the future—it’s something manufacturers are using right now. By bringing together IoT (Internet of Things) and AI (Artificial Intelligence), companies can make better decisions, work faster, and avoid costly mistakes. These technologies help reduce downtime, improve product quality, and increase overall efficiency on the production floor.

For a smart manufacturing company, this combination is key to staying ahead of the competition. As more businesses in the smart manufacturing industry turn to digital tools, those that use AI and IoT will have a big advantage. Whether it’s tracking machine performance, predicting problems before they happen, or improving how products are made, smart technology is changing how modern factories operate.

What is Smart Manufacturing and Why Does It Matter?

Smart manufacturing refers to the use of interconnected technologies, such as AI, IoT, big data, and robotics, to optimize the production lifecycle. Unlike traditional manufacturing, where systems operate in silos, smart manufacturing systems enable seamless communication between machines, people, and processes, thereby promoting agile decision-making and autonomous operations.

According to MarketsandMarkets, the smart manufacturing market is expected to grow from $108.9 billion in 2021 to $181.3 billion by 2026, at a CAGR of 10.1%.

The Role of IoT in Smart Manufacturing

The IoT forms the backbone of smart manufacturing. It connects machines, tools, sensors, and systems to enable real-time monitoring and data collection.

Benefits of IoT in Smart Manufacturing:

- Real-time visibility of operations

- Predictive maintenance through data trends

- Energy optimization

- Supply chain transparency

- Machine utilization analytics

By embedding sensors across the production floor, manufacturers can access detailed data on temperature, pressure, vibration, and energy consumption, allowing a fully digital view of their smart production environment.

How AI Enhances Smart Manufacturing

AI adds the intelligence layer to the data collected through IoT. It enables machine learning, pattern recognition, and automated decision-making. AI can:

- Predict failures before they occur

- Optimize production schedules

- Improve product quality via defect detection

- Reduce waste and improve yield

AI algorithms interpret vast volumes of sensor data in real-time, offering actionable insights that empower manufacturers to make better decisions, faster.

Integrating IoT with AI: The Perfect Synergy for Smart Manufacturing

When combined, IoT and AI create a powerful synergy that transforms traditional manufacturing into a smart manufacturing system.

1. Predictive Maintenance

IoT sensors gather machine performance data (e.g., vibration, temperature), and AI analyzes this to predict potential failures. This helps in reducing unplanned downtime and optimizing maintenance schedules.

2. Quality Control

Computer vision and AI algorithms can analyze product images from IoT-enabled cameras in real-time to detect even microscopic defects, automating and improving quality control.

3. Supply Chain Optimization

AI can analyze IoT data across the supply chain, identifying delays, optimizing inventory, and improving logistics decisions.

4. Energy Efficiency

IoT sensors track power usage while AI algorithms determine patterns and make suggestions to reduce energy waste, leading to significant cost savings.

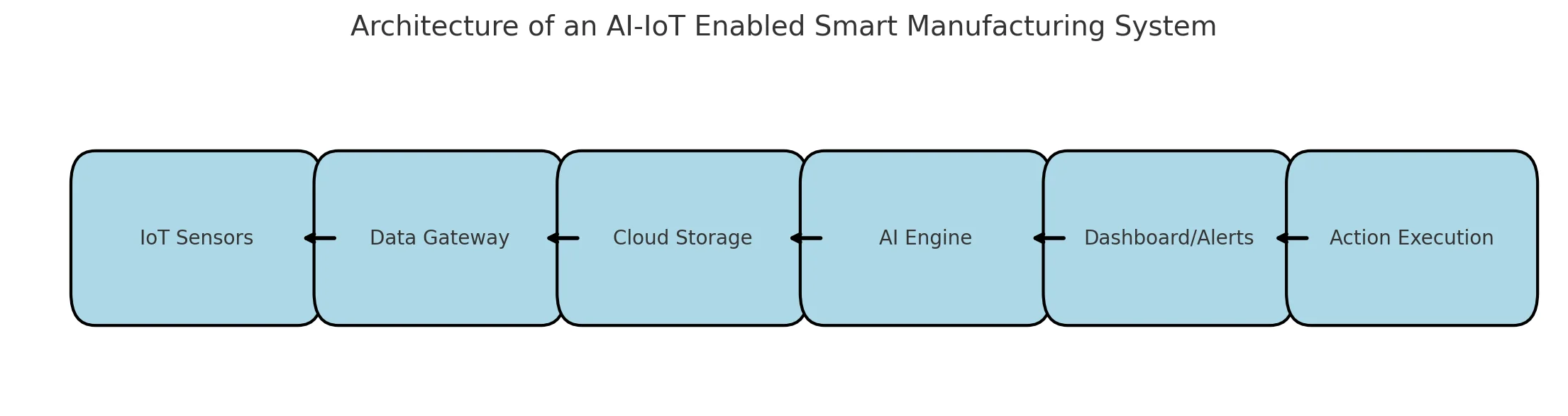

Architecture of an AI-IoT Enabled Smart Manufacturing System

This architecture enables seamless integration and feedback loops, where decisions are made and executed without human intervention, enhancing system intelligence over time.

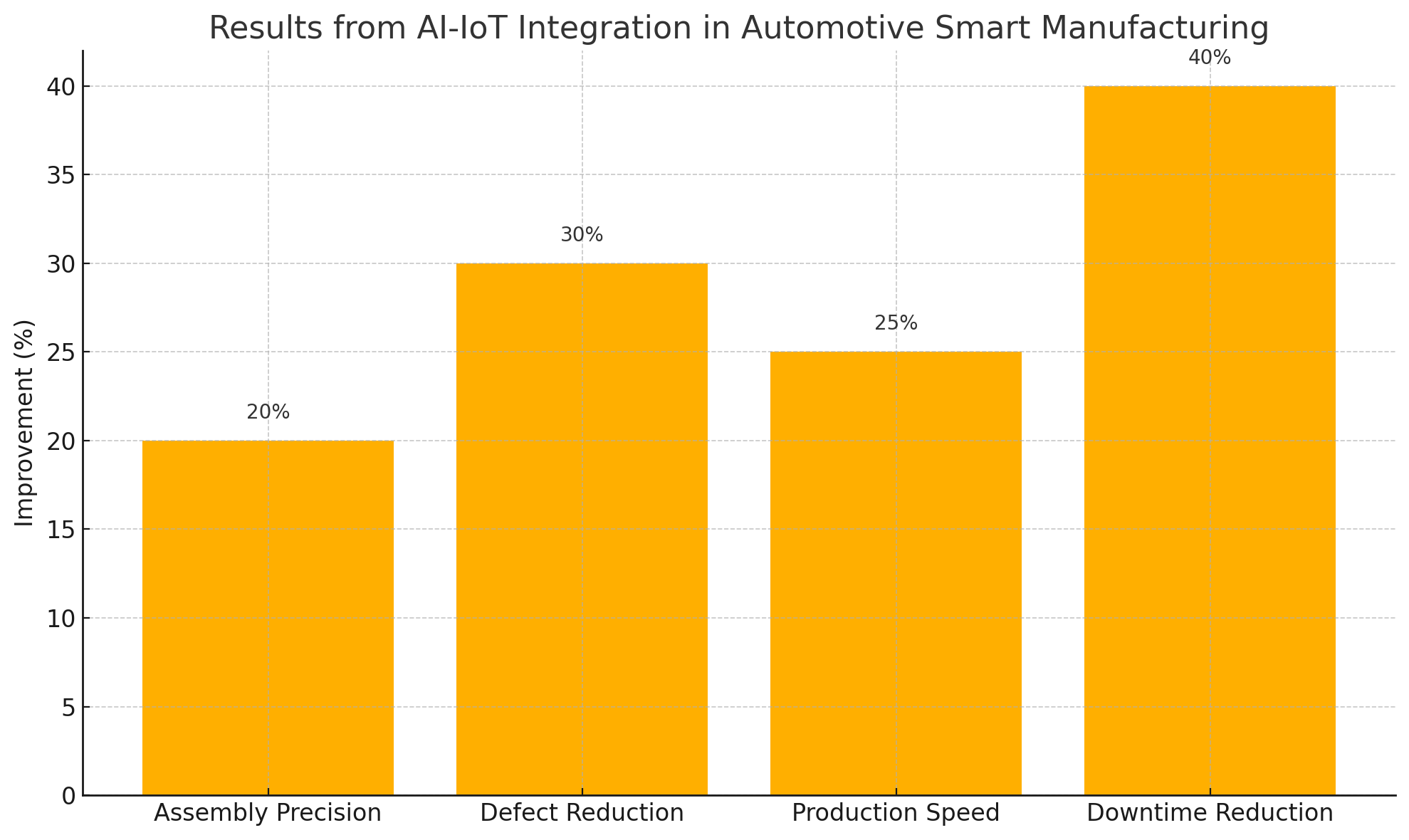

Use Case: Smart Manufacturing Company in the Automotive Sector

An automotive smart manufacturing company implemented an AI-IoT solution on their assembly line. Using IoT sensors and cameras, they collected real-time data on part alignment and torque measurements. AI models processed the data to detect anomalies instantly.

Results Achieved:

- 20% improvement in assembly precision

- 30% reduction in defects

- 25% increase in production speed

- 40% reduction in machine downtime

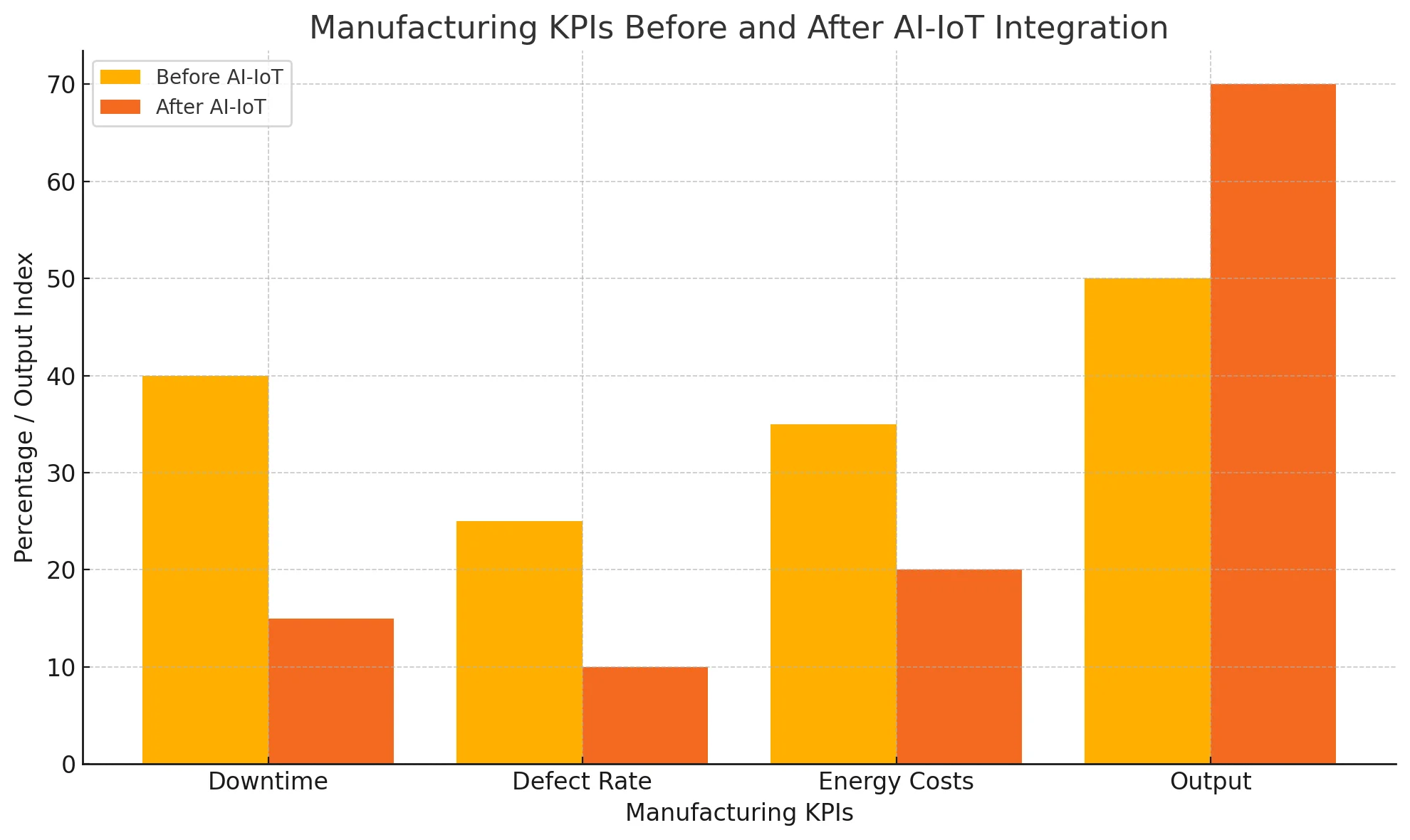

Smart Manufacturing is Data-Driven and Insight-Powered

At the core of every successful smart manufacturing industry initiative is a robust data strategy. AI thrives on high-quality, real-time data from IoT networks.

Deloitte reports that manufacturers using AI-driven analytics achieve 20% to 25% improvement in productivity and 15% to 30% reduction in costs.

Graph: How AI + IoT Impacts Manufacturing KPIs

Challenges in AI-IoT Integration and How to Overcome Them

1. Data Silos

Solution: Implement centralized cloud systems to unify data collection and analysis.

2. Cybersecurity Risks

Solution: Enforce robust IoT encryption protocols and AI-powered anomaly detection systems.

3. High Implementation Cost

Solution: Start with pilot projects, prove ROI, and then scale systematically.

Future of Smart Manufacturing: Where Are We Headed?

As AI models evolve and 5G enhances IoT connectivity, we will see:

- Fully autonomous factories

- Digital twins for process simulation

- Self-healing machines

- AI-powered design and prototyping

These advancements will cement the dominance of smart manufacturing systems across industries.

Conclusion

Integrating IoT with AI is the cornerstone of smart manufacturing transformation. It empowers companies to create resilient, adaptive, and intelligent production environments. For any smart manufacturing company aiming to scale and lead in the smart manufacturing industry, this integration is not optional—it’s essential.

If you haven’t already begun your AI-IoT journey, now is the time. The future of smart manufacturing depends on your ability to innovate, optimize, and automate.